Services

About Us

HISTORY

The Metal Shop was started in 2002 by Duane Swift. After spending 30 years in the Navy and working for another exhibit company, the opportunity to start a small business was offered. From the very humble beginnings of one drill press and MIG welder, Duane was off and running. Since that date, the company has rem...

Our Client Products

The Metal Shop Introduction Video

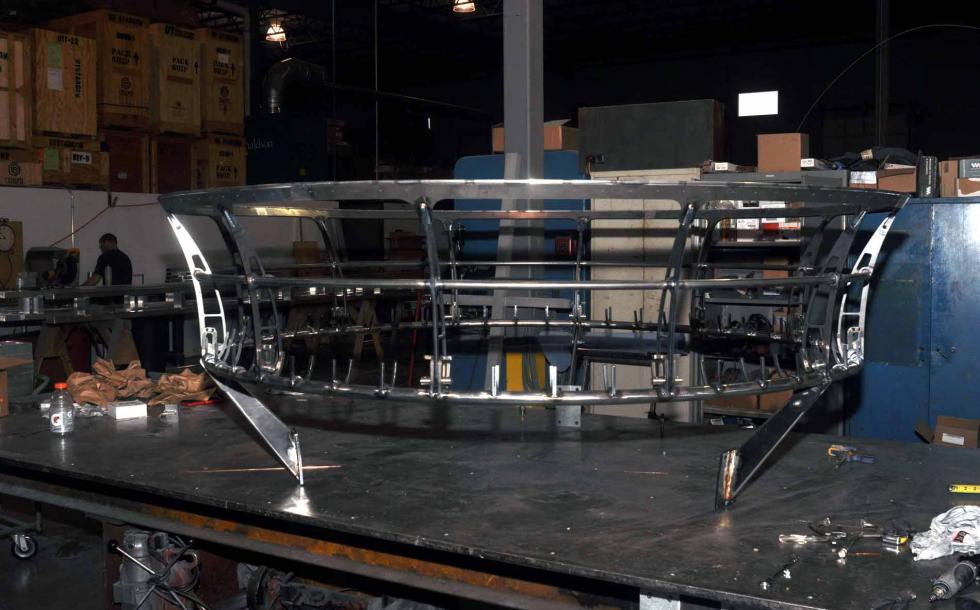

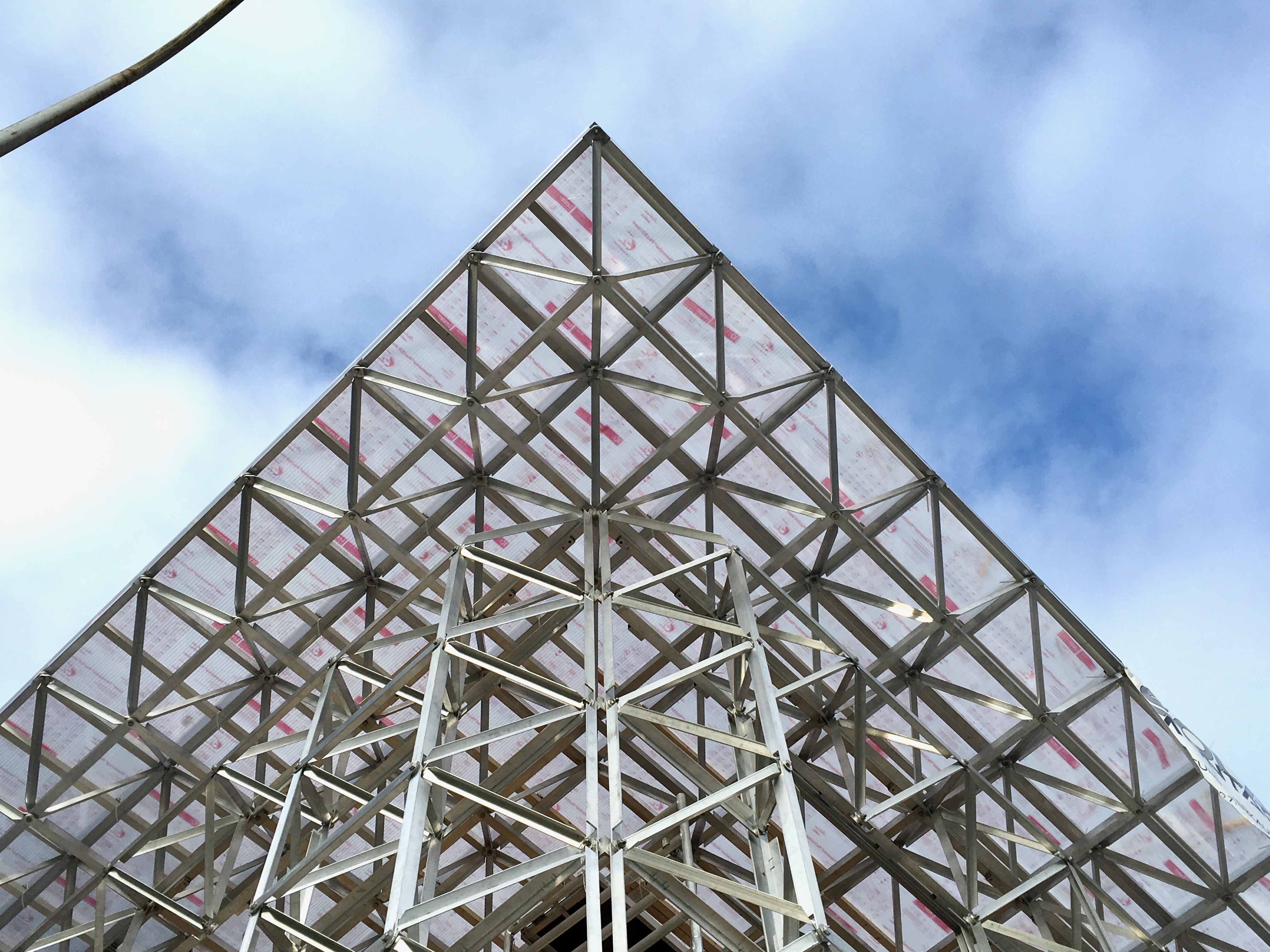

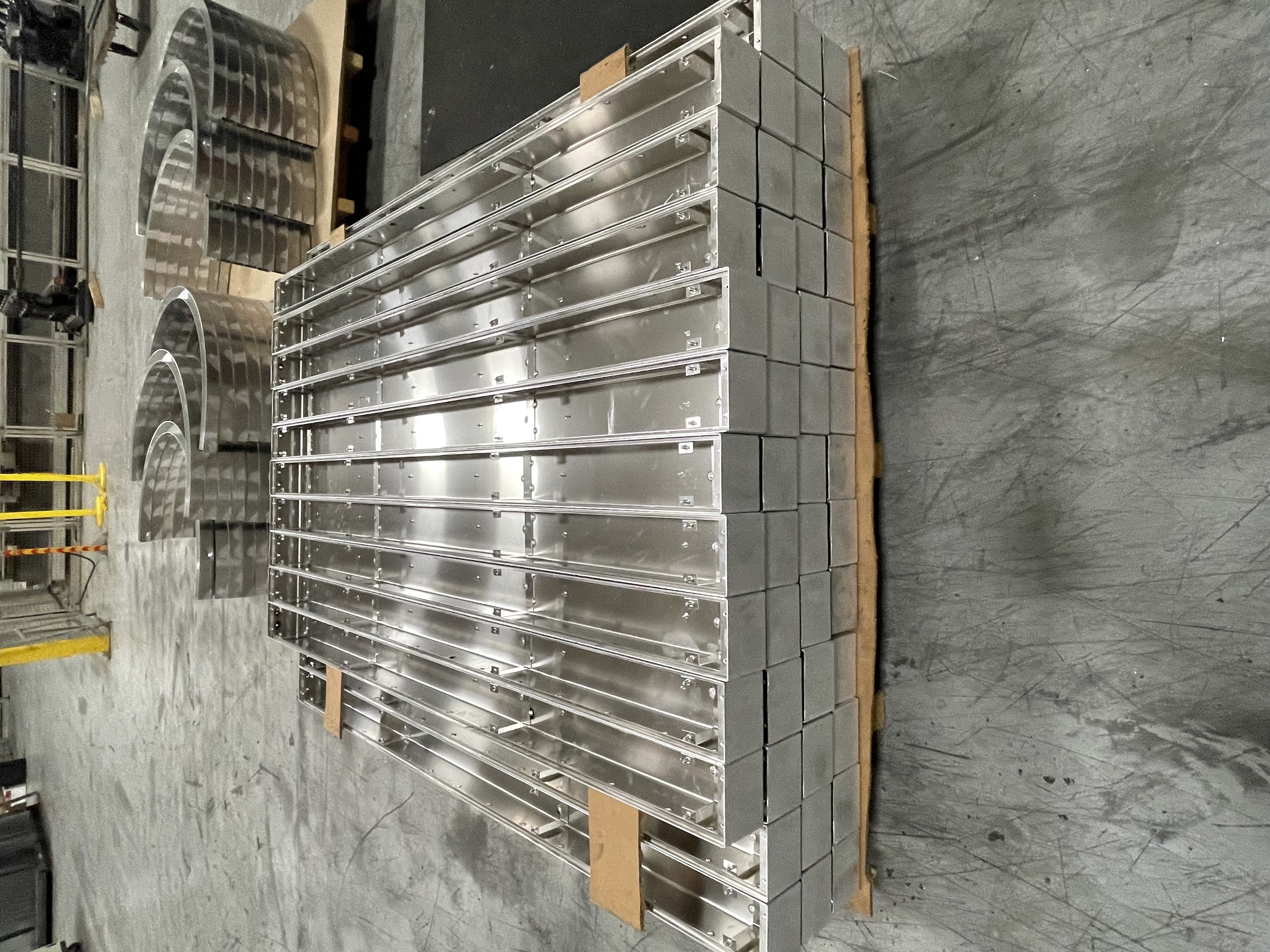

With over 50 years of fabrication experience, The Metal Shop has amassed a diverse range of skills and knowledge drawn from a variety of industries.

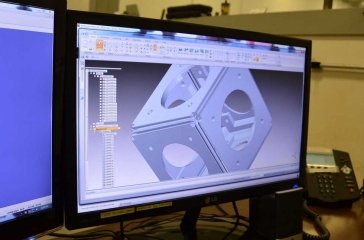

Quick Links: Metal Fabrication, Bending, CNC Machining, Aluminum Welding & Much More!

metal bending and forming services wisconsin aluminum metal fabrication wisconsin custom metal fabrication services custom aluminum structure fabrication custom aluminum fabrication wisconsin robotic welding services tube laser cutting services millwaukee tube bending services chicago